DGMK-Project Automotive Fuels

Investigation and evaluation of the influences on the deposition formation in diesel injectors as well as experimentally based modelling by means of a non-engine injector deposition test bench

TU Bergakademie Freiberg, Institute for Energy Process Engineering and Chemical Engineering, Klaus Hildebrandt

Even more than a decade after the widespread introduction of biofuels in the middle distillate sector, new biofuels and additives, but also other alternative middle distillates, continue to enter the market. In addition to HVO and other raw materials for the production of FAME and new fuel blends such as R33 (7 % FAME, 26 % HVO), future fuels such as "algae fuels" are already being discussed. Liquid hydrocarbons from tar sands, shale oil deposits or alternative fossil sources such as natural gas (GtL) are also under discussion. At the same time, modern common-rail diesel engines will have to meet the continuously tightening emission standards (e.g. Euro VI). To this end, each injection process involves several pre-, main and post-injection events lasting less than a millisecond. These are combined with continuously increasing injection pressures and correspondingly smaller opening cross-sections of the injectors. Since 2007, an increasing number of injector malfunctions have been observed in the field due to deposits inside the injector, the so-called "Internal Diesel Injector Deposits" (IDID). The aim of the project is to clarify individual effects on the formation of IDID and to transfer the findings to a calculation model.

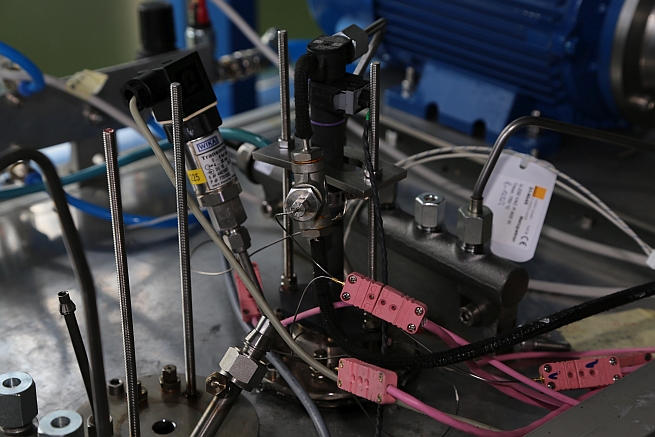

Investigating the influences on IDID with the engine test provided for this purpose, the DW10 test, is expensive and fuel-intensive. Furthermore, it is only possible to differentiate individual influences on the engine to a limited extent. OWI will therefore use the non-engine injector deposit test bench set up in the "ENIAK" project funded by the BMEL via the FNR to investigate the individual influences, such as injector temperature, injection pressure and operating cycle, on IDID formation. The knowledge gained will be incorporated into the formation of a calculation model at the TU Bergakademie Freiberg. Based on this, a test program will be developed for the ENIAK test bench, with which fuels and additives can be examined in a quick test, reproducibly and realistically, for their tendency to form IDIDs.

The project has been completed. The DGMK research report 784 is available.

Dr. Martin Müller

Chairman

ERC Additive GmbH

Buchholz

Jan Ludzay

Head of the Refining and Product Application Department

IGF - Industrial Collective Research

Federal Ministry for Economic Affairs and Energy (BMWi)