DGMK-Project Lubricants

Investigations of the Failure Mechanisms of Grease-Lubricated Rolling-Bearings - The Significance of Aging Different Tickness Systems

Dr. Markus Grebe

OWI Science for Fuels gGmbH affiliated Institute of the RWTH Aachen

Dagmar Kuckelberg

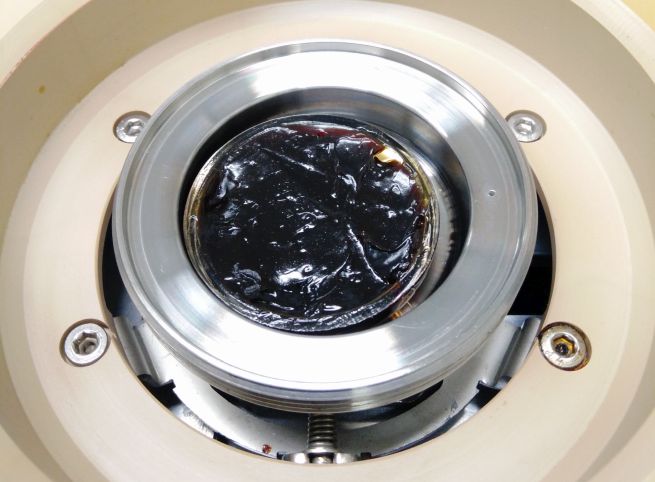

Continuous further developments in application technology with the aim of higher economic efficiency and power density place ever greater demands on lubricating greases. This is particularly true in the field of rolling bearings, where greases are sometimes used at high speeds and in wide temperature ranges. Thus, an increased radiant heat input into rolling bearing greases occurs in electric and hybrid vehicles or engine compartment downsizing concepts. DGMK project 788 "Screening test method for lubricating greases" shows that the loss of the lubricating effect of a grease is strongly influenced by thickener degeneration. Recent publications by other scientists confirm this hypothesis and confirm the need for research. In greases based on soap thickeners, this effect apparently occurs well before the actual base oil ages and is therefore life-limiting. The catalyst effect of the cage material has a different - and so far unknown - effect on this effect than on the classical oil ageing. The project aims to clarify which factors ultimately play the decisive role and how the effect can be positively influenced.

The interdisciplinary cooperation between the OWI and KTM, which was already successful in Project 788, is to be continued in this project. At the OWI, the focus will again be on chemical issues, whereas the KTM will concentrate on mechanical-dynamic testing and structural verification. The focus of the follow-up project will be the change of the thickener structure as a result of mechanical, thermal, oxidative and catalytic stress. The chemical and structural changes are to be detected and investigated using state-of-the-art analytics and microscopy (structure: scanning electron microscopy, partly "cryo-REM", light microscopy, rheology and electrophoresis; ageing: FTIR (incl. modern evaluation methods), HPLC-MS, GC-MS, PDSC, TGA and DSC; elements: ICP). This project is also based on an empirical approach, i.e. numerous laboratory tests on ageing as a function of temperature, ambient medium and catalytic elements will be carried out and evaluated. A certain focus is on the so-called RapidOxy test, as this is gaining in importance, especially in industry. A new screening test rig for dynamic fat ageing is to be developed at KTM. The main part of the tribological tests will be application-oriented rolling bearing tests on the multi-user rolling bearing test rig.

DGMK Research Report 820 has been published.

Thomas Litters

Chairman

FUCHS LUBRICANTS GERMANY GmbH

Mannheim

Jan Ludzay

Head of the Refining and Product Application Department

Federal Ministry of Economics and Climate Protection

IGF - Industrial Collective Research