DGMK-Project Lubricants

Influence of the Coefficient of Friction and Power Loss on the Processes in the Sealing Zone of an Oil-Elastomer Pairing

Institut für Modellierung und Berechnung

Dr. Volkert Wollesen, Gerrit Weiser

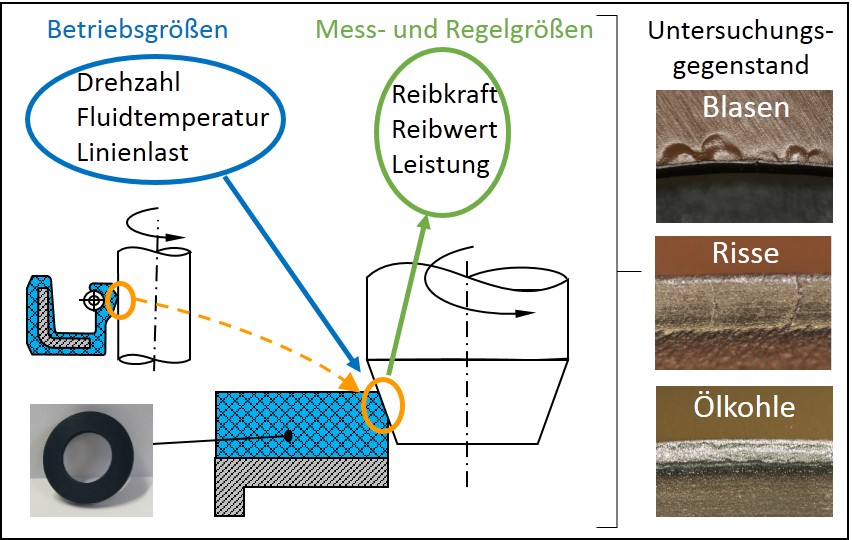

The interactions between oil and elastomer occurring during operation of a rotary shaft seal often lead to damage (e.g. bubbles, cracks, oil carbon) in the sealing zone. The evaluation of the damage patterns at the sealing edge of an rotary shaft seal close to the operation/test run is a decisive criterion for the release of the sealing system. In this research project, the effect of individual operating parameters, such as oil sump temperature, circumferential speed and line load, on the occurrence of such damage patterns on the rotary shaft seal tribometer will be investigated. The formation of bubbles, as a highly complex damage pattern, will be investigated using an exemplary oil-elastomer pairing under different operating conditions. In addition, the test time and the power loss in the sealing zone will be considered as an effect on the damage. A defined power loss can be set on the rotary shaft seal tribometer by controlling one or more operating parameters.

By systematically investigating the influences of the operating parameters, areas of influence are determined which lead to the damage patterns relevant to practice in the oil-elastomer pairing being investigated. On the basis of the findings obtained, an efficient test specification for general oil-elastomer pairings is to be derived. Furthermore, fundamental findings regarding the origin and degree of damage are to be shown. Since the problem of the interaction of oil and elastomer in rotary shaft seal use is widespread and cross-industry, there is a very wide field of application for the rotary shaft seal tribometer. By using the rotary shaft seal tribometer, more detailed knowledge of the damage patterns can be gained.

The focus of the investigations is a laboratory lubricant which, in fluoroelastomers, has a tendency to both blistering and bubble-like swelling. At a constantly adjusted power loss, the influence of the operating parameters sump temperature, speed and line load on the damage to the elastomer is investigated by specific variation of these parameters. Detailed evaluation of the elastomer samples determines under which operating conditions only swelling occurs and when bubbles form.

Merle Kühn

Chairwoman

Afton Chemical GmbH

Hamburg

Jan Ludzay

Head of the Refining and Product Application Department

IGF - Industrial Collective Research

Federal Ministry for Economic Affairs and Energy (BMWi)