DGMK-Project Lubricants

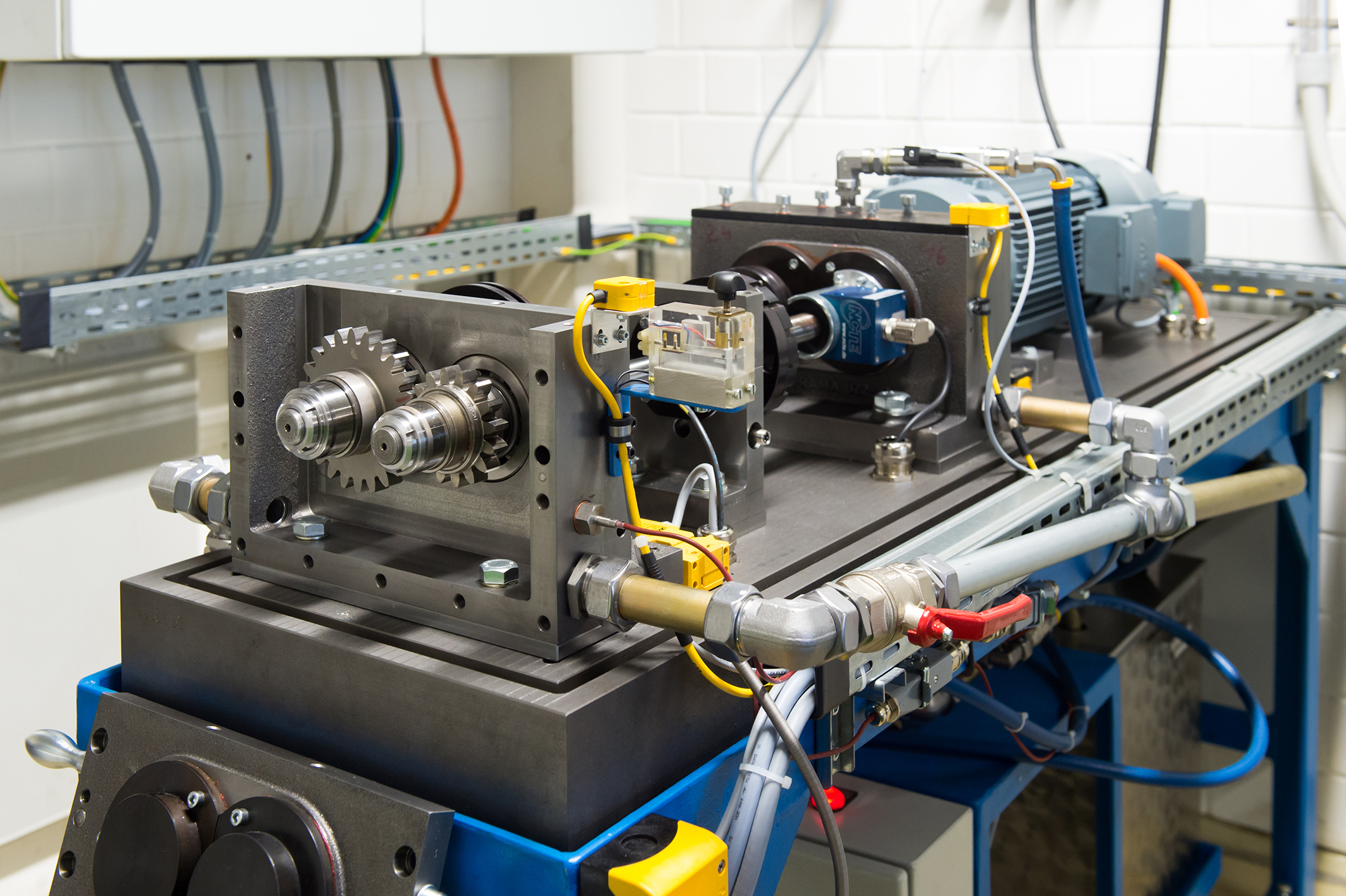

Determination of the Load Capacity of Gear Pairings under Spray Lubrication with Flow Greases

Gear Research Centre (FZG)

Andreas Dobler

In the project it is to be examined to what extent the results for the scuffing and wear behaviour of case-hardened grease-lubricated gear wheel pairings with immersion lubrication (DGMK 670) can be transferred to the conditions with spray lubrication. If necessary the test procedure (A/2,76/50) should be adapted or extended. Furthermore, it should be clarified whether, taking into account the results on the pit load-bearing capacity and service life (DGMK 591, 670 and 673), a lubricant factor ZL for lubricating greases can be derived by means of supplementary tests with spray lubrication.

The main focus of the work is on running tests to determine the wear behaviour of case-hardened gears with injection lubrication as well as running tests to supplement DGMK 591, 673 and 670 on pitting life with injection lubrication.

The project was completed with the publication of the DGMK research report.

Jan Ludzay

Head of the Refining and Product Application Department

IGF - Industrial Collective Research

Federal Ministry for Economic Affairs and Energy (BMWi)