DGMK-Project Fuel Oils

Investigation on Avoiding High-Molecular Aging Products in Middle Distillates with Alternative Blend Components under Technical Conditions

Sebastian Feldhoff, Karin Brendel

ITMC Institute of Technical and Macromolecular Chemistry at RWTH Aachen University,

Dr. Markus Küppers

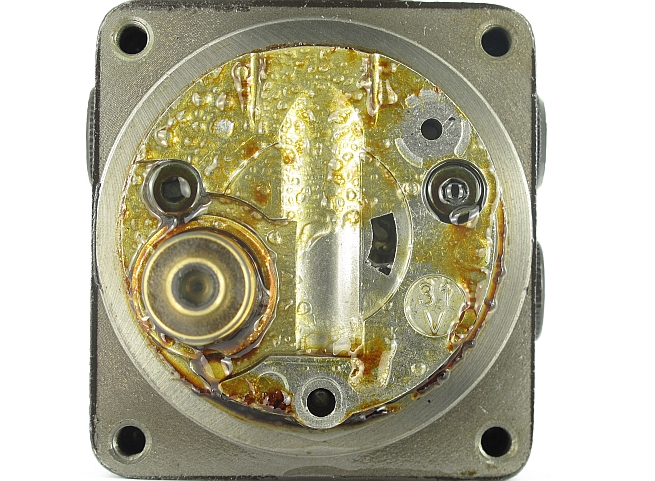

Biocomponents can lead to technical challenges in the various middle distillate applications (e.g. motors and heaters), especially with regard to their stability. Surprisingly, the technical phenomena are similar despite different technologies. Corrosion and polymer formation occur, and the consequences of these ageing phenomena can be operational failures. Previous research activities have opened up the possibility of reproducing these phenomena in a controlled manner for both fuel oil EL S-arm and diesel fuels by using hardware-in-the-loop tests, i.e. test benches that can test fuel-carrying components, fuels and additives. However, there is still great uncertainty about the deposit formation itself and its underlying specific ageing mechanisms. As a result, there is still insufficient damage management in technical applications.

In the project, components from fuel oil burner systems are to be tested with regard to their resistance to ageing products of fuels with biogenic contents, whereby the results can be transferred to other middle distillates such as diesel or aviation turbine fuels. In this context, the tolerance against relocation or blockages caused by sediments being formed is primarily considered. In addition to long-term storage, a laboratory test procedure for testing individual components will be developed and an overall system analysis will be carried out. Thus, both the fuel and the components are to be tested in interaction with the fuel. Another aim is to determine the influences of the fuel oil components and the interactions with the FAME and HVO used on the sedimentation tendency of blends. This will allow a targeted investigation of component installation and the development of avoidance strategies that will contribute to increasing the operational safety of the fuel oil burner systems when using biofuel oils.

The DGMK research report 778 was published. The project has been completed.

Susanne Seehack

Chairwoman

ERC Additive GmbH

Buchholz

Jan Ludzay

Head of the Refining and Product Application Department

IGF - Industrial Collective Research

Federal Ministry for Economic Affairs and Energy (BMWi)