DGMK-Project Lubricants

Interactions Between Surface Active Additives and the Effect on the Wear Protection of Rolling Bearings

GFE Joint Laboratory for Electron Microscopy at RWTH Aachen University: Prof. Dr. Joachim Mayer, Dr. Silvia Richter

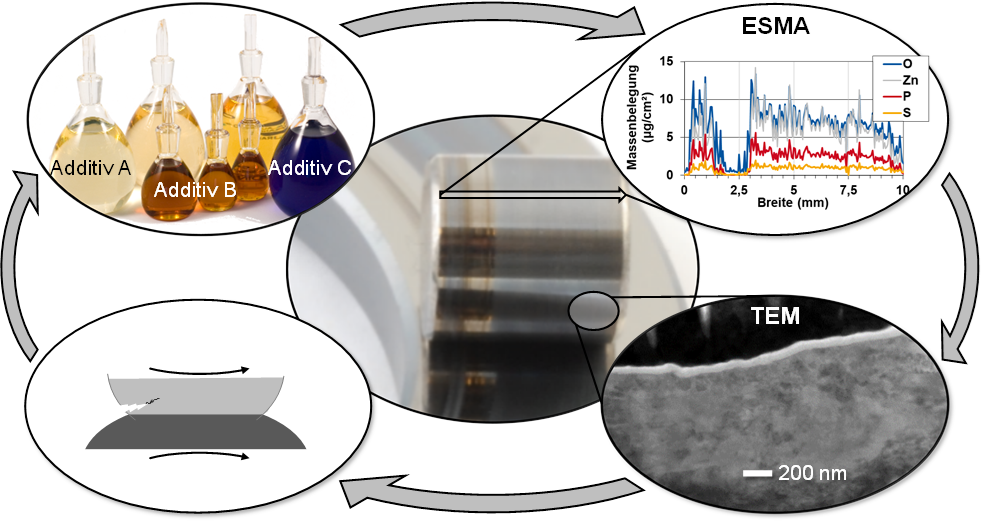

Appropriate lubrication enables the efficient and safe operation of rolling bearings. In practice, additives added to the lubricant fulfil specific tasks in order to meet increasing demands on machine components. Polar additive groups such as wear and corrosion protection additives function in each case by interacting with tribologically stressed surfaces. Therefore, competition or synergies are possible on the surface, which leads to additive combinations that are sometimes incompatible or ineffective for the application. For this reason, a singular consideration of the respective additive group is not sufficient. The aim of this project is therefore to determine the sensitivity of the effectiveness with regard to the composition of a combined wear and corrosion protection additive in lubricating oils. Furthermore, it is necessary to identify interactions of additves in the lubricant, and surface competition in the formation of boundary layers by analysing the structure, durability and protective effect of boundary layers.

The project includes experimental investigations of combined wear and corrosion protection additives in oil-lubricated rolling bearings. By evaluating the wear behaviour as a function of the oil composition, the sensitivity of the effectiveness of combined wear and corrosion protection additives can be determined, whereby selected operating parameters of the rolling bearings are systematically varied. By accompanying microanalyses of the structure, durability and protective effect of the resulting additive-based boundary layers, interactions of the additive groups can be evaluated. Overall, a model of the combined boundary layer structure of wear and corrosion protection additives is derived. Furthermore, suitable additive combinations for an optimised boundary layer formation are identified.

The funding decision from the BMWK has been received. The project was launched on March 1, 2022.

Dr. Axel Figge

Chairman

CARL BECHEM GMBH

Hagen

Jan Ludzay

Head of the Refining and Product Application Department

Federal Ministry of Economics and Climate Protection