DGMK-Project Lubricants

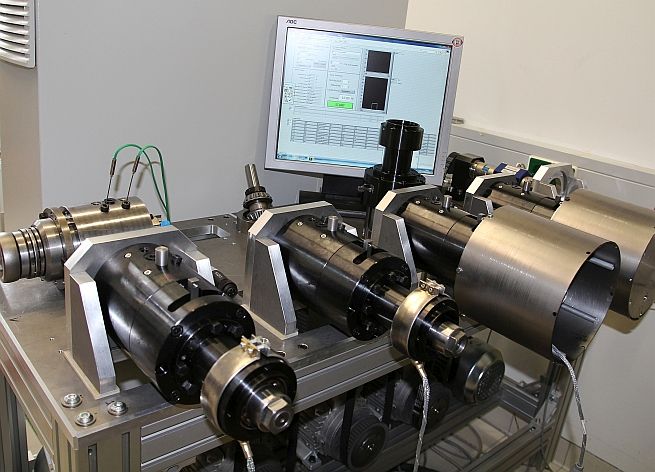

Development of a Screening Test Method for Lubricating Greases by Coupling Thermo-Oxidative Test Methods with a Mechanical-Dynamic Multi-Location Station Bearing Test Rig

Simon Eiden

Competence Center Tribology, Mannheim University of Applied Sciences

Dr. Markus Grebe

Continuous further developments in application technology with the aim of higher economic efficiency and power density place ever greater demands on lubricating greases. This is particularly true in the field of rolling bearings, where greases are sometimes used at high speeds and large temperature fluctuations. Thus, an increased radiant heat input into rolling bearing greases occurs in electric and hybrid vehicles or engine compartment downsizing concepts. Tribological testing machines such as the FE8 and FE9 are not suitable for the basic development or condition monitoring of lubricating greases, because the individual tests are too time-consuming and cost-intensive. In the grease development stage, several iterative development cycles are typically necessary, with costs multiplying with each cycle. Therefore, it is necessary to develop a screening test method with low time expenditure by coupling thermo-oxidative test methods with a mechanical-dynamic multi-location rolling bearing test for grease development and condition monitoring.

In addition to the development of a screening test method for the quick and easy determination of the grease operating life, it is also necessary to determine the oxidation stability as a function of the load duration by means of delta value considerations and to determine a residual operating life of the greases. The exact test conditions must be determined by determining the reaction-kinetic data. During ageing or use in the tribological system, evaporation or coking effects may occur depending on the operating or ambient conditions. This not only changes the composition or the surface condition, which greatly impairs the lubricant's lubricating behaviour, but also influences the further ageing behaviour. By combining oxidation stability tests with thermogravimetric or calorimetric analyses, the influence of evaporation and coking effects on the stability and the determination of the activation energy can be correlated. Based on this, effects on the lubrication behaviour within the tribological system can be derived.

Bernhard Koch

Chairman

FUCHS LUBRICANTS GMBH

Mannheim

Jan Ludzay

Head of the Refining and Product Application Department

IGF - Industrial Collective Research

Federal Ministry for Economic Affairs and Energy (BMWi)