DGMK-Project Lubricants

"Varnishing" tendency of lubricating oils - investigation of influencing factors and layer structure

IFOS gGmbH Institute for Surface and Coating Technology: PD Dr. Johannes L'huillier, Stefan Emrich

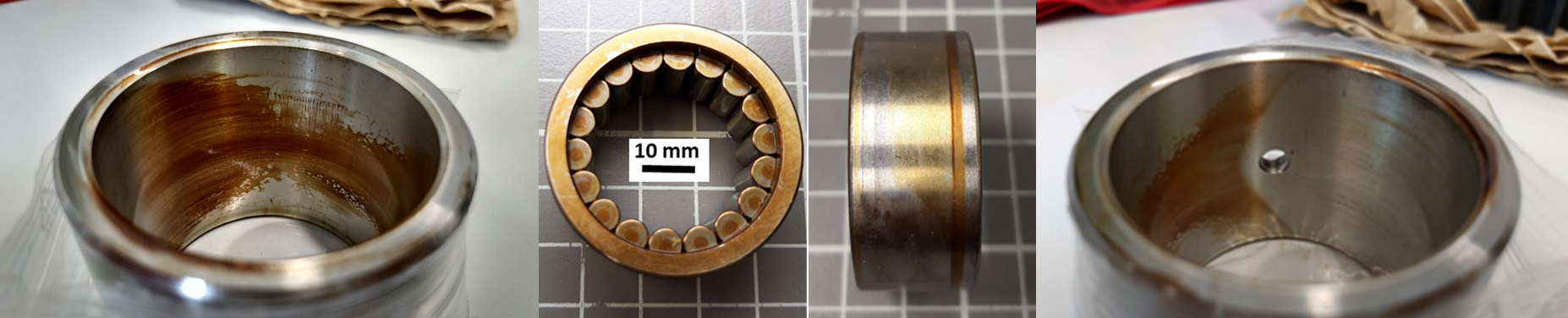

Under critical operating conditions such as high thermal and mechanical loads, often in combination with small quantities of oil or in the presence of catalytically active elements, high-speed plain bearings in various industrial plants exhibit a varnish formation that is dangerous for the operation of the plant. The varnish-like layer is deposited on tribological functional surfaces and changes the system properties. In valves and filters, the layers can lead to blockage and thus to system failure. Until now, the problem was mainly limited to high-speed shafts in turbines. However, ever smaller oil quantities combined with ever higher power density and less polar base oils are now also causing problems in hydraulic systems and other systems. The currently established test methods are primarily aimed at evaluating the varnishing potential, i.e. the predicted tendency of a lubricant to form varnish. Time-consuming and cost-intensive system tests have to be carried out for oil and additive development. However, these provide largely unreliable forecasts, as the formation of varnish layers cannot be attributed solely to the respective lubricant properties, but must rather be derived from the properties of the tribological system as a whole and from system-specific parameters such as temperature distribution, pressures and flow rates.

The underlying research approach pursues a paradigm shift from a lubricant-focused perspective to a fundamental analysis of the formation of the coating layer as a function of the tribological stress collective and the technological boundary conditions. With the help of a new laboratory test methodology, the risk of varnishing can be better predicted for industrial companies depending on the stress collective of the tribological system.

The project is funded by the Federal Ministry for Economic Affairs and Energy on the basis of a decision by the German Bundestag. The grant notification from the BMWE is available with a start date of 01.07.2025.

Jan Ludzay

Head of the Refining and Product Application Department

Federal Ministry for Economic Affairs and Energy (BMWi)

You need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information